Top 3 Reasons Why Manufacturing Needs Managed SD-WAN

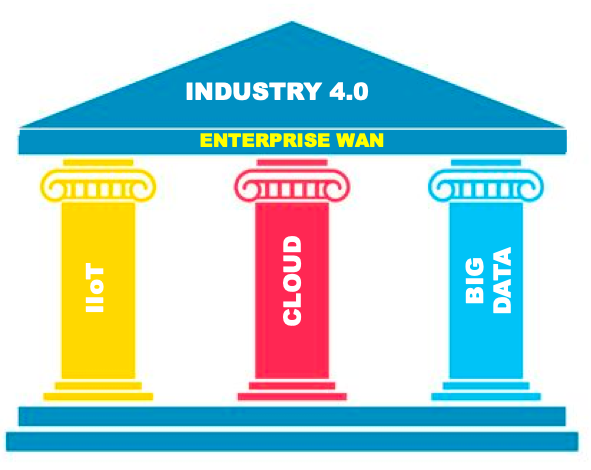

Once considered a laggard, the manufacturing sector is fast catching up on Digital Transformation initiatives. Central to this transformation are technologies like the Industrial Internet of Things (IIoT), the cloud, and big-data analytics. Introduction of IoT in the manufacturing ecosystem has streamlined the production process by providing real-time feedback and alerts from the factory floor. Vast amounts of data thus collected has paved the way for the meaningful application of machine learning and artificial intelligence algorithms for fault prediction, quality assurance etc. Cloud adoption in this sector is also on the rise, largely due to the increased availability of cloud-based manufacturing systems alongside office productivity suites like Office365 and CRM systems like Salesforce.

Together, IIoT, cloud and big data are the technologies driving digital transformation in manufacturing. But for these technologies to be successful, the quality of connectivity is critical. The Enterprise WAN should have a robust architecture that is capable of transporting vast amounts of data generated from IIoT devices on the factory floor, prioritize mission-critical data from cloud-based manufacturing systems, support office productivity and CRM SaaS applications, while ensuring that machines running AI and ML algorithms have access to data lakes.

Industrial IoT and Big Data

Industrial IoT is an important part of the digital transformation in manufacturing. IIoT devices on the factory floor collect vast amounts of data that will be classified, analyzed and stored in data lakes. Traditional backhaul architectures were primarily designed to handle north-south traffic, that is from users to applications, and not east-west traffic from sensors to applications and servers.

Aryaka’s solution includes tools like MyAryaka a portal for configuring the network and monitoring network performance. In addition, traffic from IIoT devices can be segmented and bespoke policies can be applied.

Cloud Applications

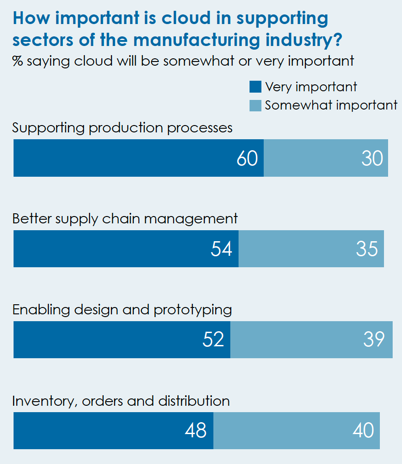

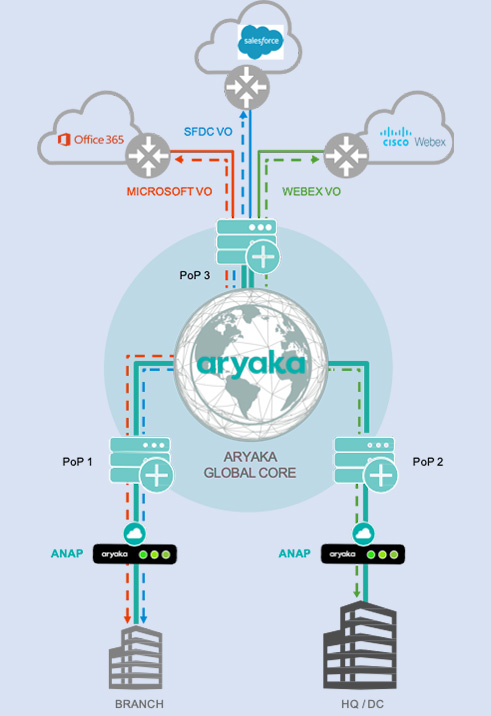

According to a survey conducted the Economist Intelligence Unit (EIU), over 50% of executives in the manufacturing sector believed that cloud was very important especially in critical areas of manufacturing like production process, supply chains and in design & prototyping. In addition to these domain-specific SaaS applications, firms are also adopting SaaS solutions for office productivity like office 365, customer relationship management system like Salesforce and UCaaS applications like WebEx. It is important to ensure that each of these traffic categories is segmented and treated differently.

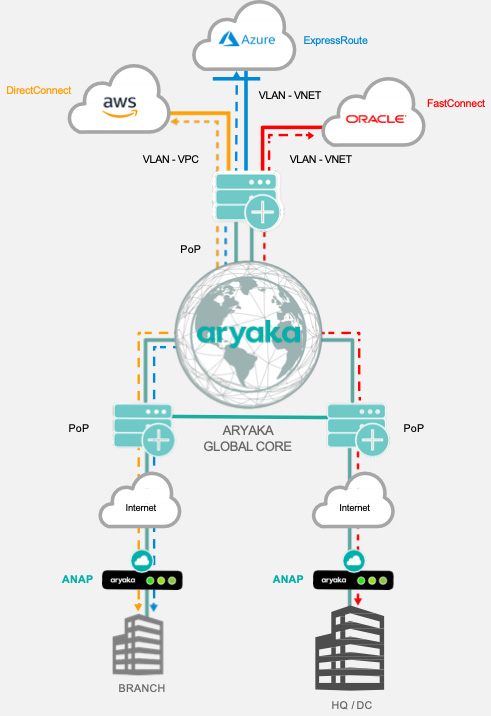

Aryaka’s solution is built for a cloud-first world. The solution comes with built-in WAN optimization, security and application acceleration. Aryaka provides direct connectivity to Azure, AWS and Oracle for applications hosted on these IaaS platforms.

IaaS Direct Connectivity

Virtual Office for Cloud Apps

For other SaaS deployments, a Virtual Office is the preferred solution. A ‘Public Virtual Office’ (VO) is Aryaka’s solution for providing connectivity and improving the performance of cloud-based office applications that are accessed over the internet. A VO is an Aryaka virtual router with Layer 4 stateful firewall capability and uses a public IP address. It also provides an optimization container and multi-segment TCP architecture to reduce the RTT.

ARYAKA SD-WAN SOLUTION FOR INDUSTRY 4.0

Aryaka’s fully managed SD-WAN is designed as a cloud-first solution that supports digital transformation initiatives in the sector.

IoT

Aryaka’s solution provides a low latency transport for mission critical IoT traffic and ensures security through segmentation of IoT traffic. A management portal offers a real time view of the traffic.

Cloud Acceleration

Aryaka provides a cloud first solution that can identify all major applications and accelerate them based on a bespoke policy. It provides out of the box off ramps to popular cloud service providers.

Big Data Delivered

Aryaka’s solution includes a fully meshed layer 2 core network that ensures low latency and packet loss. Built-in WAN optimization and segmentation ensures mission critical data is prioritized.

A CASE IN POINT

A case in point is Makino, a leading maker of manufacturing tools for a range of vertical industries, who was running out of patience with the wide area network linking company facilities in North America, Asia, and Europe. It was taking too long for data to synchronize among locations, increasing the chance that employees would be working off of old data, and the company realized that its static, legacy MPLS backbone would be a limitation when it came to moving aggressively to the cloud.

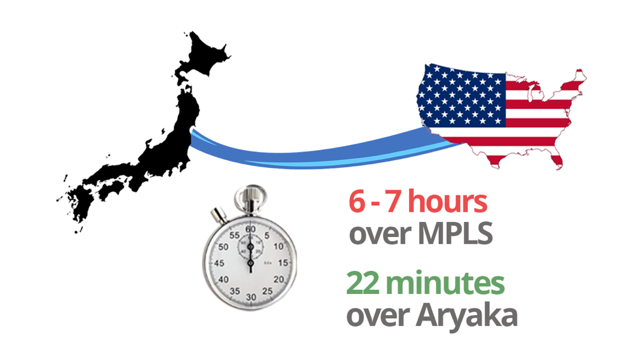

The job of making machine manufacturing equipment involves transferring large data files of machine schematics, drawings, and statistics. With legacy MPLS networks, it was taking 6-7 hours to synchronize data between the Tokyo headquarters and the tech center in Mason, Ohio.

MPLS was also too static for the company’s needs. MPLS deployment times were notoriously long because circuits had to be coordinated with multiple carriers all the way down to the last mile, creating months of delays in new site rollouts and reducing the ability to set up new locations quickly. A final nail in the coffin of MPLS was the fact that the company had plans to move 90% of its applications to the cloud in the coming years.

THE SOLUTION

Makino chose Aryaka’s fully managed SD-WAN service, a fully meshed Layer 2 network with 30+ PoPs around the world. To link all their facilities, all that Makino had to do was connect their facilities to a local PoP using short, dedicated Internet links. From there, the company’s traffic was optimized (using patented technology) for transport across Aryaka’s dedicated facilities to any site in the world. The fact that Aryaka uses deduplication and caching technologies to groom traffic, limit packet loss and deliver low (and consistent) latency end-to-end, promised to improve Makino’s data synchronization efforts. It also paved the way for migration to the cloud and improved the performance of voice and video communications among the company’s far-flung operations.

Check out our whitepaper, CIO Solutions for Big Data and Manufacturing, which looks at the convergence of Operational Technology (OT) and Information Technology (IT) and the challenges it brings to manufacturing.