SD-WAN Best Practices for Manufacturing and Digital TransformationHow IT Can Help Global Enterprises Increase Productivity up to 20x

In a recent study conducted by Aryaka, the average data response time for a 200MB file ranges from 68 to 135 minutes over Internet based network infrastructures, depending on the distance. If you calculated the amount of customers most global manufacturing firms handle on a daily basis, waiting for files to travel at that rate can lead to days of lost productivity and severely impact the bottom line.

Product specs built with CAD/CAM applications such as Autodesk AutoCAD and DS Solidworks can range from machine parts to corporate complexes to small 3D models for consumer goods. Depending on the scope of the project, files can easily end up being being 1GB+.

Imagine if these files are being collaborated with on a global scale:

- Design is completed in Asia

- Production is handed off to the United States

- Testing conducted in Europe

- Production is handed off to the United States

With the wait time for these files to travel from one continent to another at the rate mentioned above, global manufacturing firms will find data synchronization to be a major bottleneck and a critical factor when determining if a project is completed on time or is be delayed.

“If one of our employees came in and responded to a call from an end-user who needed to order parts…if that data transfer wasn’t current…we could commit to ordering something that we actually didn’t have,” explained Darren Sargent, Infrastructure Engineer for global manufacturing leader, Makino. “And that causes delays in being able to service our customers.”

Digital Transformation Requirements to Improve Manufacturing Production

Analysts and experts predict manufacturing, like other industries, will go through a major revamp to meet the demands of today’s digital world; this will also include enterprise networking.

When Sargent and his colleagues at Makino decided upon their digital transformation strategy to improve productivity and collaboration between their continental offices, they considered a few options:

- The Status Quo: In the past, MPLS and WAN Optimization hardware had been implemented at office locations to improve performance. However, as Makino began to acquire more sites and build out international locations, implementing each site with this legacy infrastructure would not only be cost prohibitive, but result in long project times to deploy and implement.

- The Next Big Thing: SD-WAN has been touted as a panacea for all things related to the enterprise network. It’s a major consideration due the ability to set up an enterprise WAN in record time, but there are a few things to consider before deploying an SD-WAN for digital transformation:

- Does the SD-WAN provider deliver global connectivity? (Is the network included?)

- Is the solution completely dependent on the Internet or can it leverage a private network?

- Will the solution improve application performance, or will you need to rely on additional hardware to solve that issue?

- How quickly can sites be set up? Are you looking at hours, days, weeks, months?

For manufacturing companies to meet the demands of delivering large CAD/CAMfiles from one remote (branch?) location to another, a unique set of network requirements must be in place:

- A global network with carrier or MPLS-grade quality to provide fast and reliable connectivity worldwide

- Accelerated access to every SaaS, PaaS, and IaaS platform

- WAN Optimization layered on top of the network to increase application performance for end-users around the globe

- Simple and quick deployment with on-demand scalability for faster project implementation

- SD-WAN functionality to reduce complexity and cost

Manufacturing Revolutionized with Aryaka’s Managed Connectivity as a Service

Makino went with Aryaka to meet the aforementioned requirements.

With Aryaka, enterprises receive all the simplicity and cost efficiency of an SD-WAN with a full-mesh global private network built on 30 Points of Presence (POPs). The network can bypass the public Internet, practically eliminating congestion and packet loss.

WAN Optimization is layered within that network to accelerate application performance for end-users worldwide. This approach enables file transfers, as well as cloud and SaaS applications, to perform as if they were living in the local corporate datacenter.

And, since Aryaka’s solution is delivered as a service, Makino doesn’t have to buy, configure, deploy, or maintain expensive edge devices for every global location.

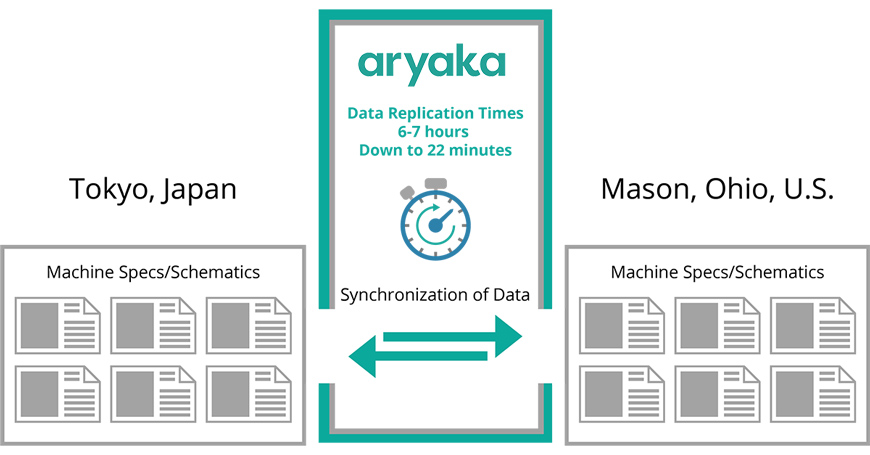

Global sites were deployed for Makino within 2-3 days. After deploying the solution, Makino noticed a dramatic, immediate improvement in performance and data transfer times. File synchronizations that previously took 6-7 hours, were now taking only 22 minutes, which enabled Makino to become more responsive and productive.

Synchronization of data between Makino headquarters in Japan to their

tech center in the U.S.

“The feedback we’ve received from executives has been very, very positive.” said Sargent, “The fact that we are able to provide that real-time data transfer, between Makino in North America, and Makino Tokyo, in less than 30 minutes, has increased efficiency significantly.”

Makino is set to embark on a future cloud strategy where 90% of their data and applications will be in the cloud by next year. Since Aryaka provides accelerated access to any application, on-premises or in the cloud, Makino now have an infrastructure in place to handle upcoming cloud migrations and can deliver data and applications to every end user as if it were hosted in the same building.

To learn more about what Aryaka can do for your manufacturing facilities, download our solution brief on improving CAD/CAM performance here.