Manufacturing Company Wins Big with New SD-WAN Service Platform

Glenn Hensley, IT infrastructure manager at Makino, a leading maker of manufacturing tools for a range of vertical industries, was running out of patience with the wide area network linking company facilities in North America, Asia, and Europe.

It was taking too long for data to synchronize among locations, increasing the chance that employees would be working off of old data, and the company’s static, legacy MPLS backbone would be a limitation when it came to move aggressively to the cloud. It was time for a change.

“Data is the lifeblood of our global business, which spans locations in Europe, North America, Japan, and other regions of Asia, so we need a robust, efficient manner to synchronize massive amounts of data for our machine specs and schematics,” Hensley says. “After all, you can only be as agile as your data infrastructure allows, and agility is critical in manufacturing today, so infrastructure performance is key, particularly when it comes to the global network that binds our locations into a seamless digital enterprise.”

The long wait

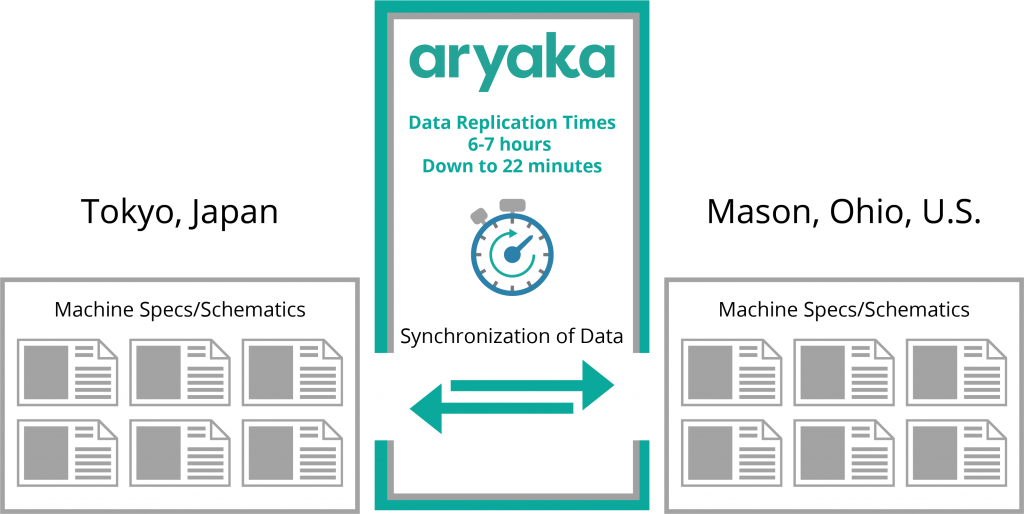

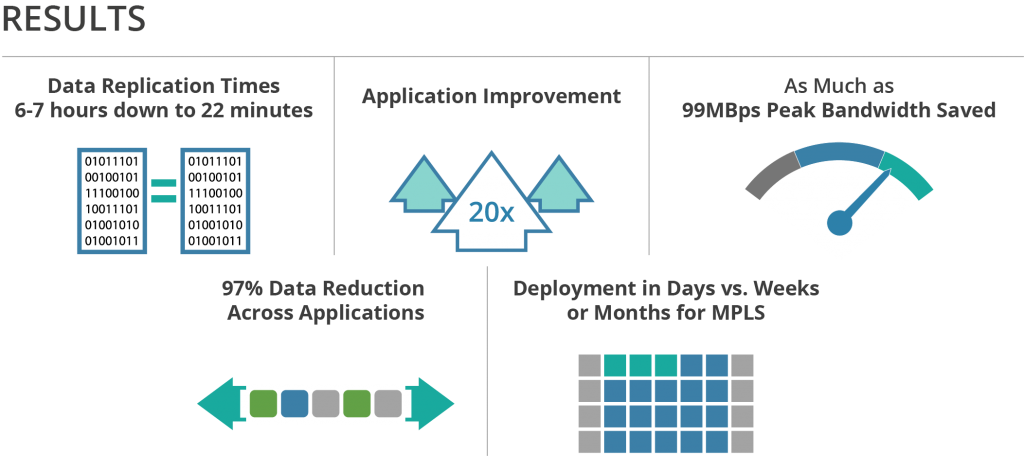

The job of making machine manufacturing equipment involves transferring giant data files of machine schematics, drawings, and statistics. “With our MPLS network, it was taking 6-7 hours to synchronize data between our Tokyo headquarters and our tech center in Mason, Ohio,” Hensley says.

Because of the time requirement, most of the data transfers had to be done overnight, and sometimes the process would not be completed when U.S. employees started their workday. “Besides being a constant drain on operational efficiency, if there were any changes to the specs it would mean a one- to two-day delay in production,” Hensley says. “The network limitations also limited our ability to provide customers with on-demand data relevant to their machines.”

MPLS was also too static for the company’s needs. “MPLS deployment times are notoriously long because circuits have to be coordinated with multiple carriers all the way down to the last mile,” Hensley says, “creating months of delays in new site rollouts and reducing our ability to set up new locations quickly.”

A final nail in the coffin of MPLS was the fact that the company had plans to move 90% of its applications to the cloud in the coming years, and Hensley wasn’t confident MPLS could support this core shift. “Our MPLS network wasn’t going to meet our ambitious digital transformation goals, so we went looking for an alternative,” he says.

What was needed

After reviewing a range of options, Hensley settled on a Software-Defined WAN from Aryaka that is delivered as a service across a global private backbone. That Layer 2 mesh network links 30 points of presence around the world, so all Makino would have to do is link their facilities to a local POP using short, dedicated Internet links. From there, the company’s traffic would be optimized (using patented technology) for transport across Aryaka’s dedicated facilities to any site in the world.

The fact that Aryaka uses deduplication and caching technologies to groom traffic and can limit packet loss and deliver low (and consistent) latency end-to-end, promised to improve Makino’s data synchronization efforts, pave the way for migration to the cloud, and even improve the performance of voice and video communications among the company’s far-flung operations.

To the rescue

Deployment was fast and painless, given the SD-WAN is delivered as a cloud-based service and consumed much like any other cloud service, and results were evident immediately.

Data synchronization went from 6-7 hours down to 20 minutes, meaning employees are always working off the right data and the company can be assured customers they are getting current information no matter where in the world they are. “Today we can provide customers with machine tool information and pricing much faster, which helps us win business, and we can be much more responsive, which has opened up new possibilities for growing our business,” Hensley says. “If that growth requires network changes, we can now modify the network in two or three days, compared to the weeks or months it would take with MPLS.”

Makino wasn’t looking to save money because the business upside far outweighed the investment, but the economics came out in its favor anyway. “We had been paying $1,200/mo. for a 10Mbps MPLS circuit that took months to deploy,” Hensley says. “With Aryaka, we were able to get twice the bandwidth for the same cost, and we deployed in a fraction of the time. Essentially, Aryaka provided us with far more bang for our buck.”

What’s more, now Makino has a global network platform to support its aggressive cloud plan. “We now have the infrastructure in place to handle the upcoming cloud migration and can deliver data and applications to every end-user as if it lived in this local data center,” Hensley says. “Aryaka’s SD-WAN is a global fast-lane for all of our business applications.”

Having that high-performance, agile data platform supporting all of its global locations ensures Makino can meet any challenge that transformation in the manufacturing sector presents.

Download our case study to learn more about how Aryaka transformed Makino’s global network to improve productivity.